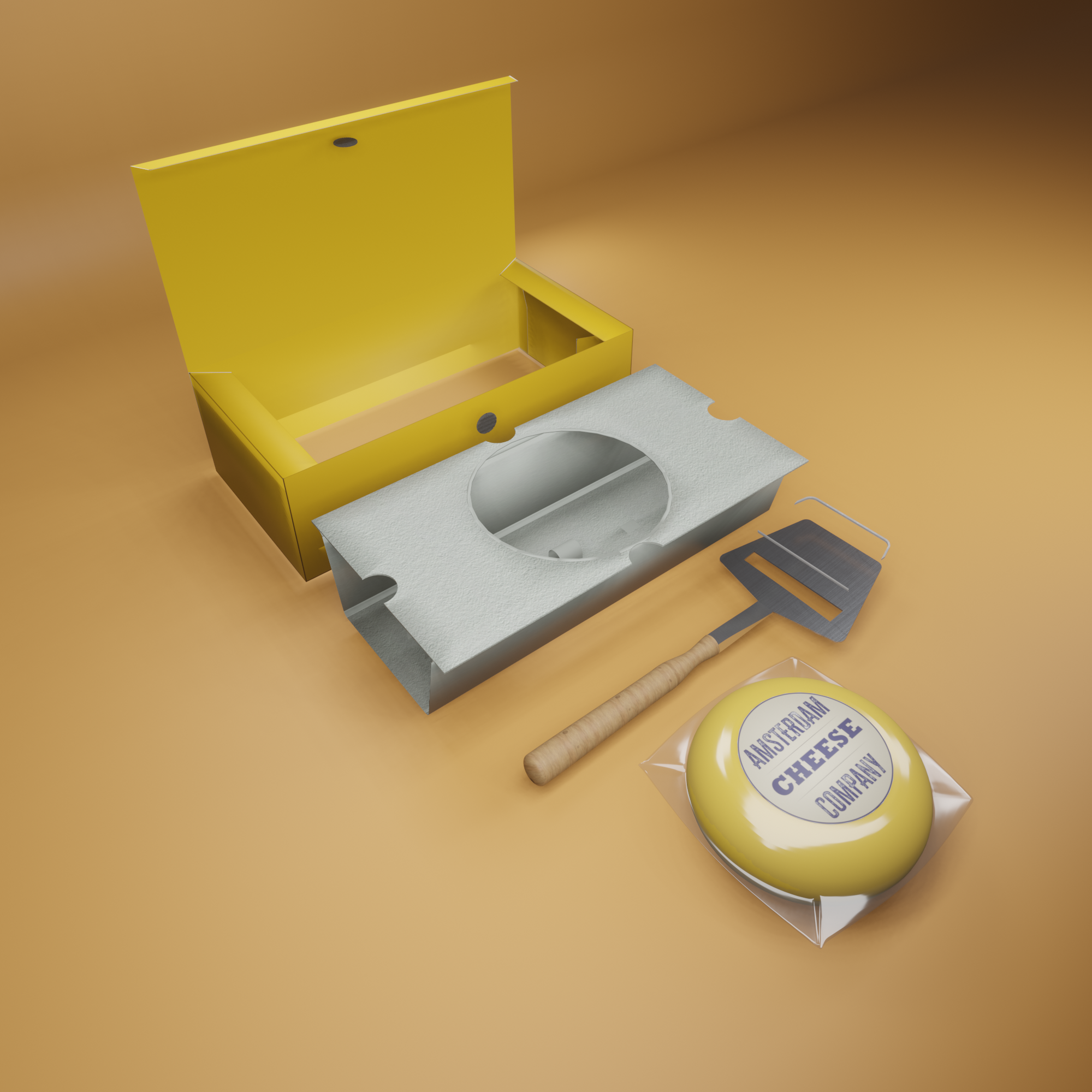

Packaging Design and Management-1

Individual project-Introduction to Packaging

Sep 22-Nov 22

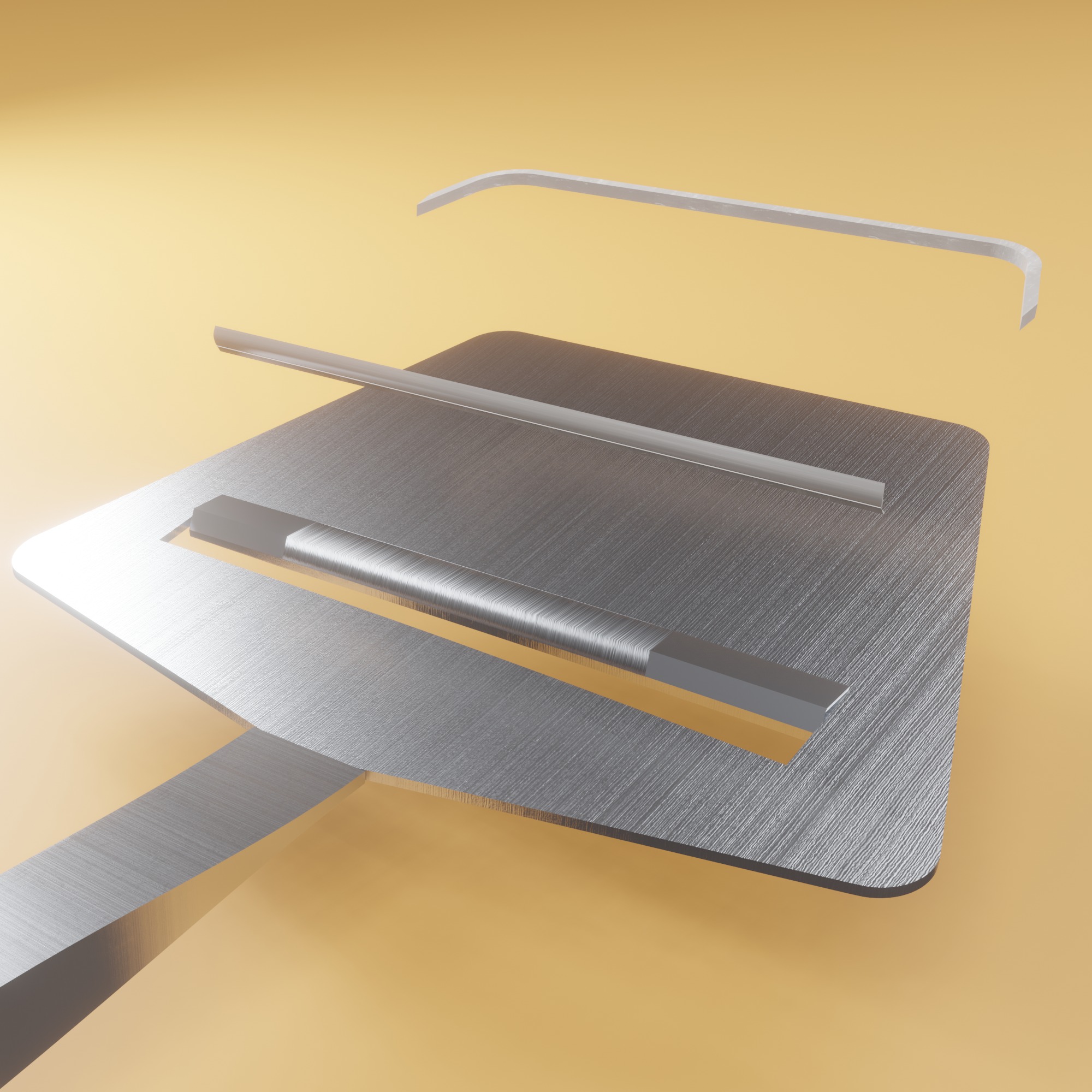

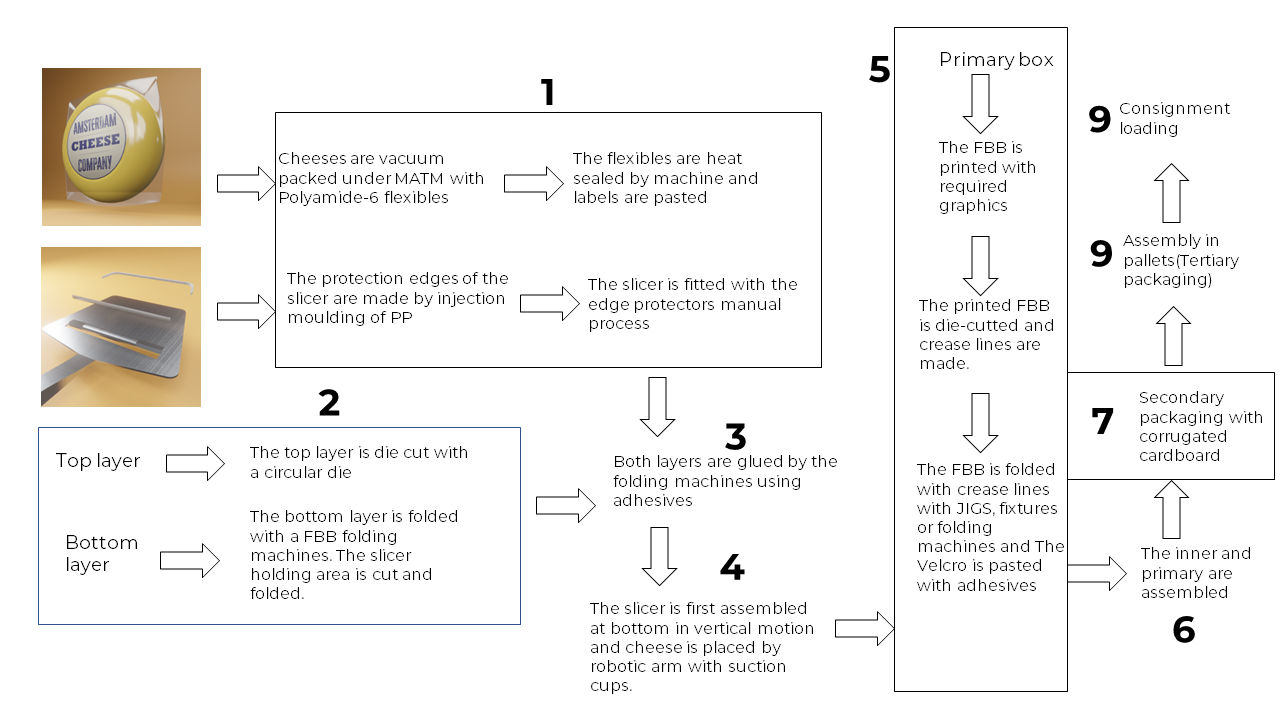

Flexibles and Laminates

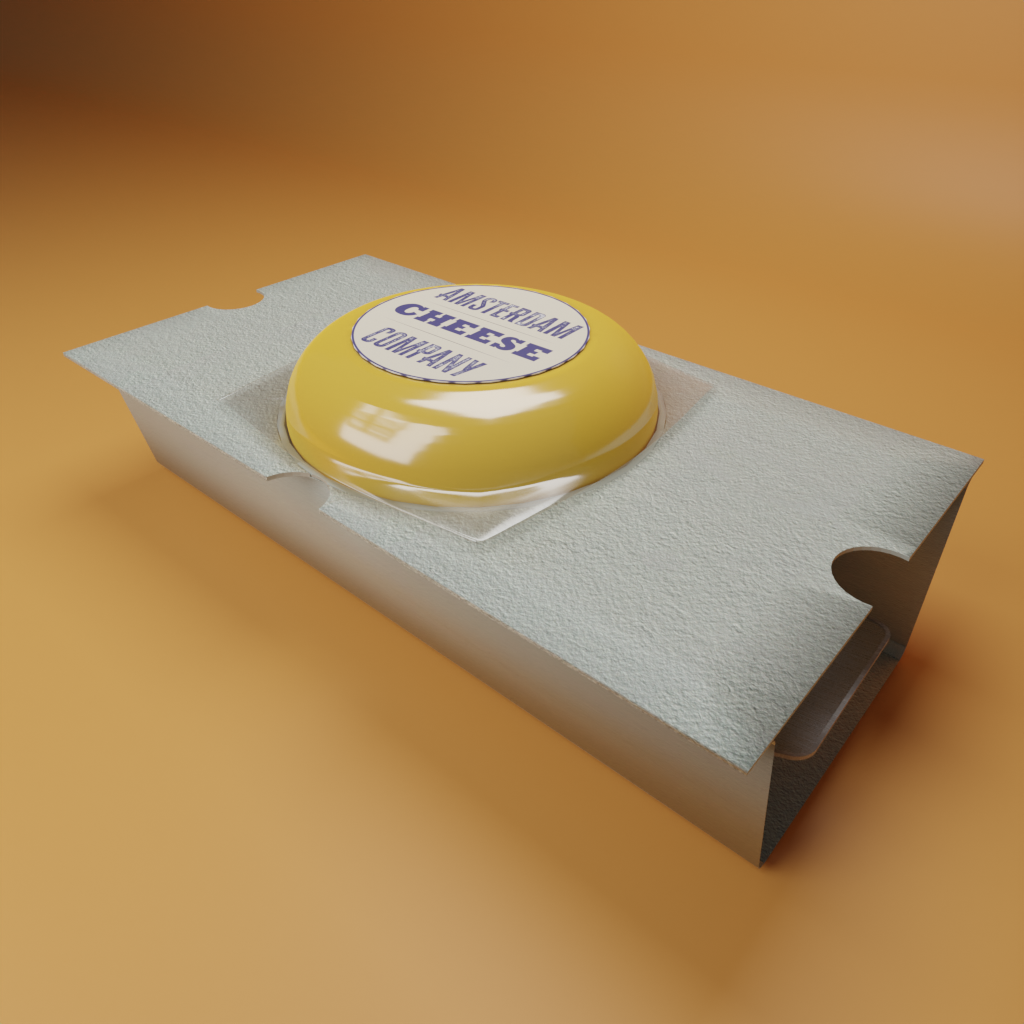

The cheese is vacuum packed with Polyamide film + LDPE film with thickness of 150 microns.

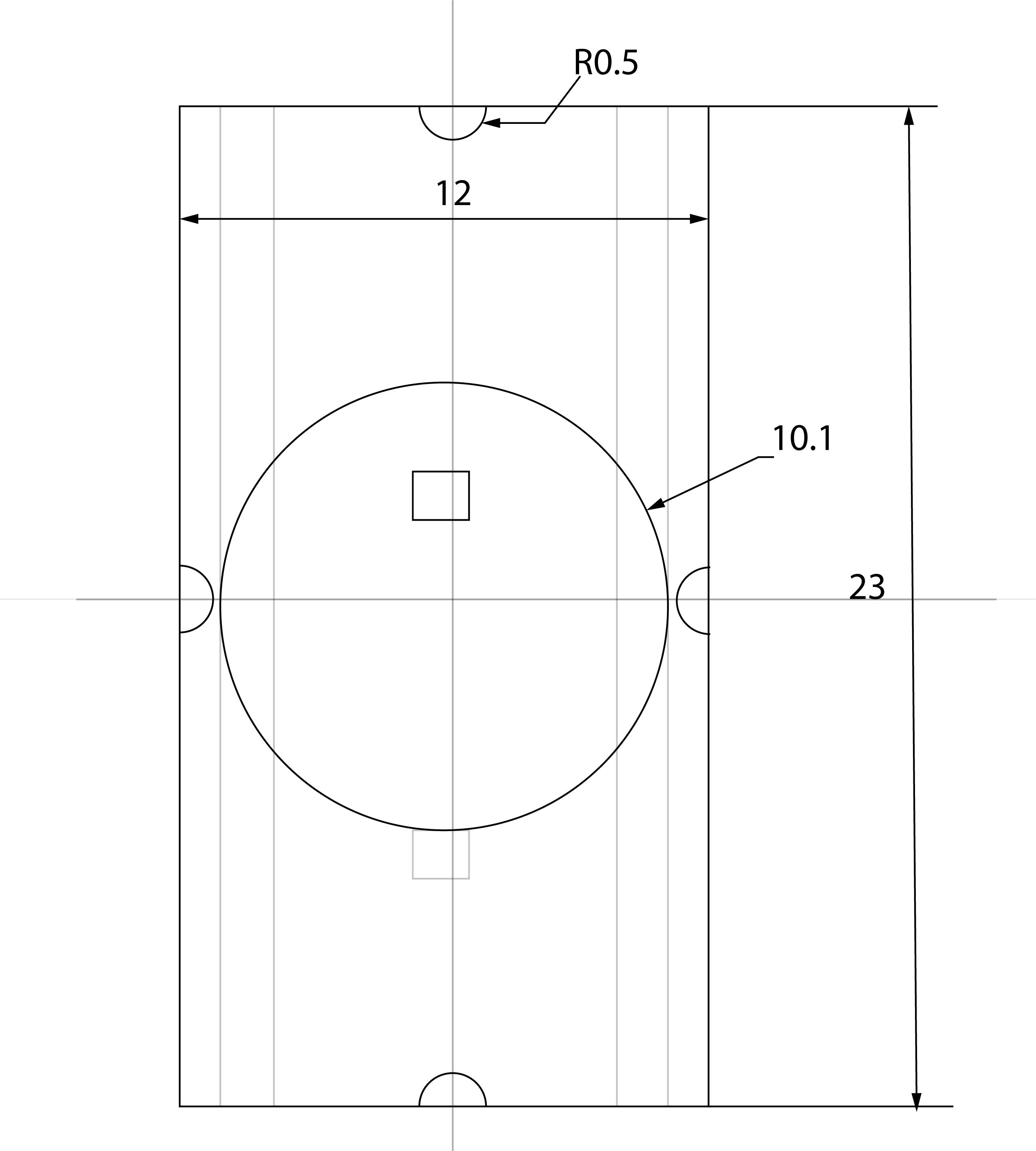

Size of the cheese wheel : 10cm(diameter) x 4 cm(depth)

Size of PA-6 film: 12cmx12cm

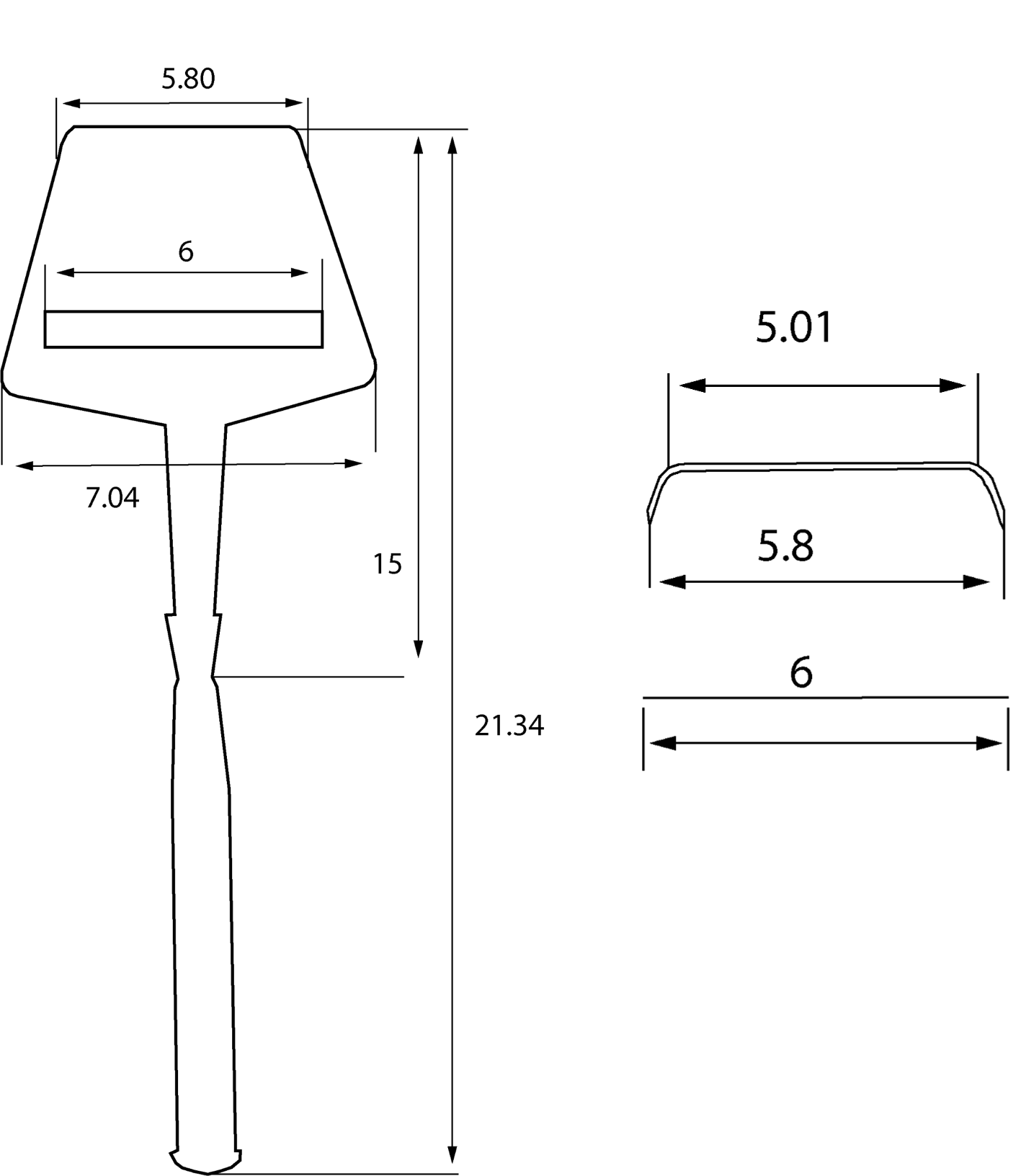

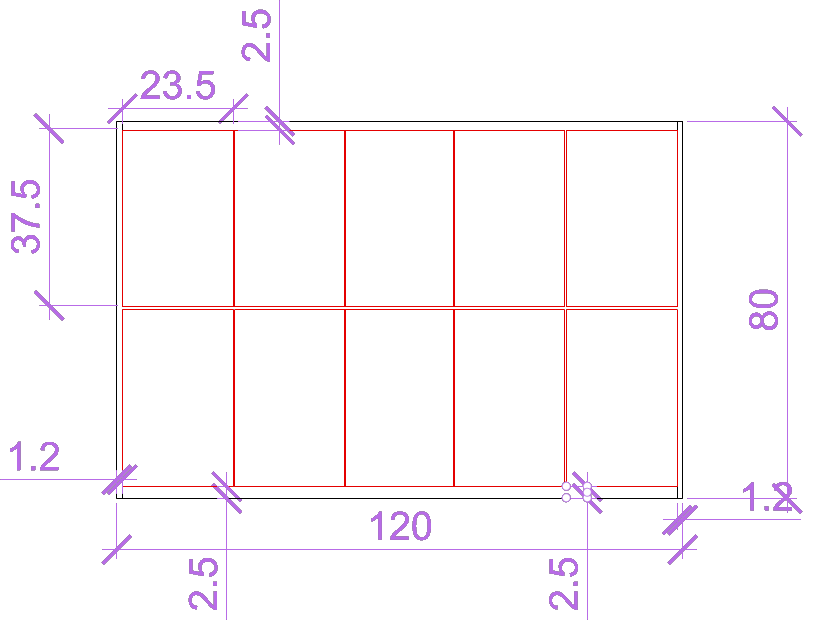

Rigid Plastics

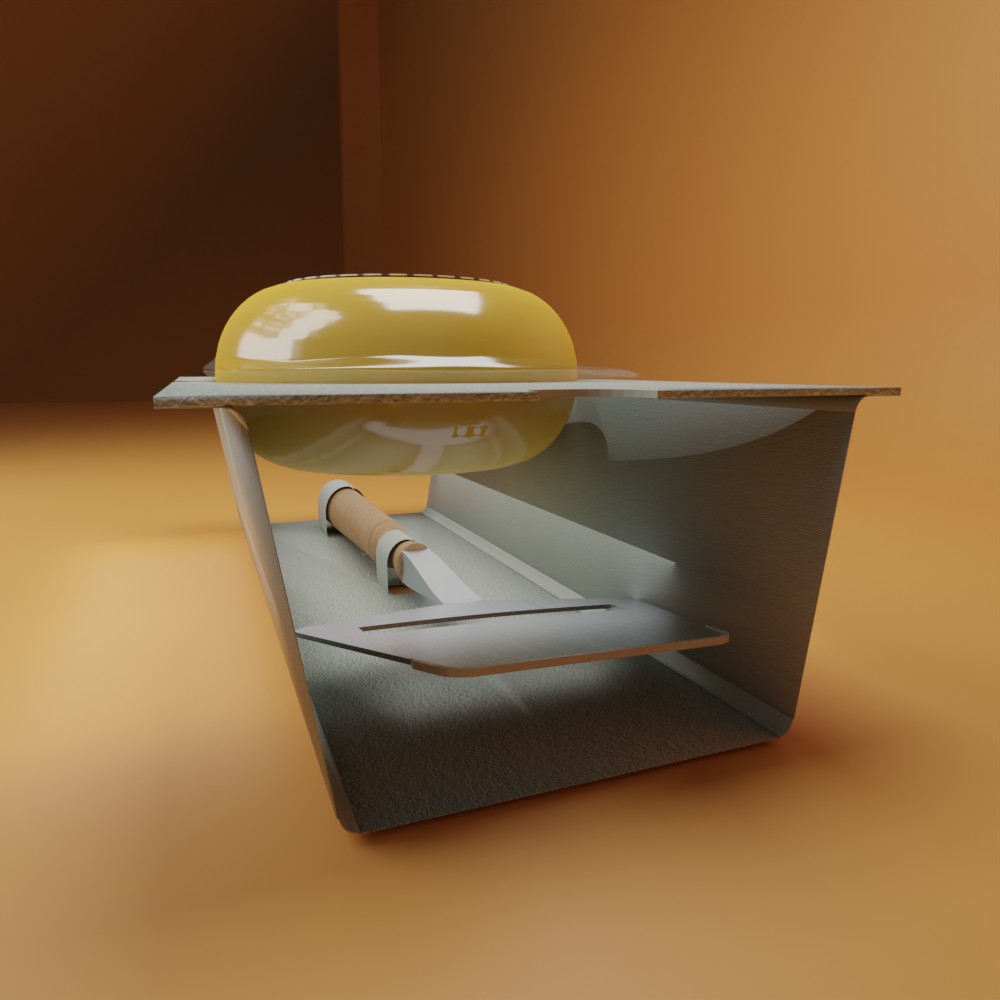

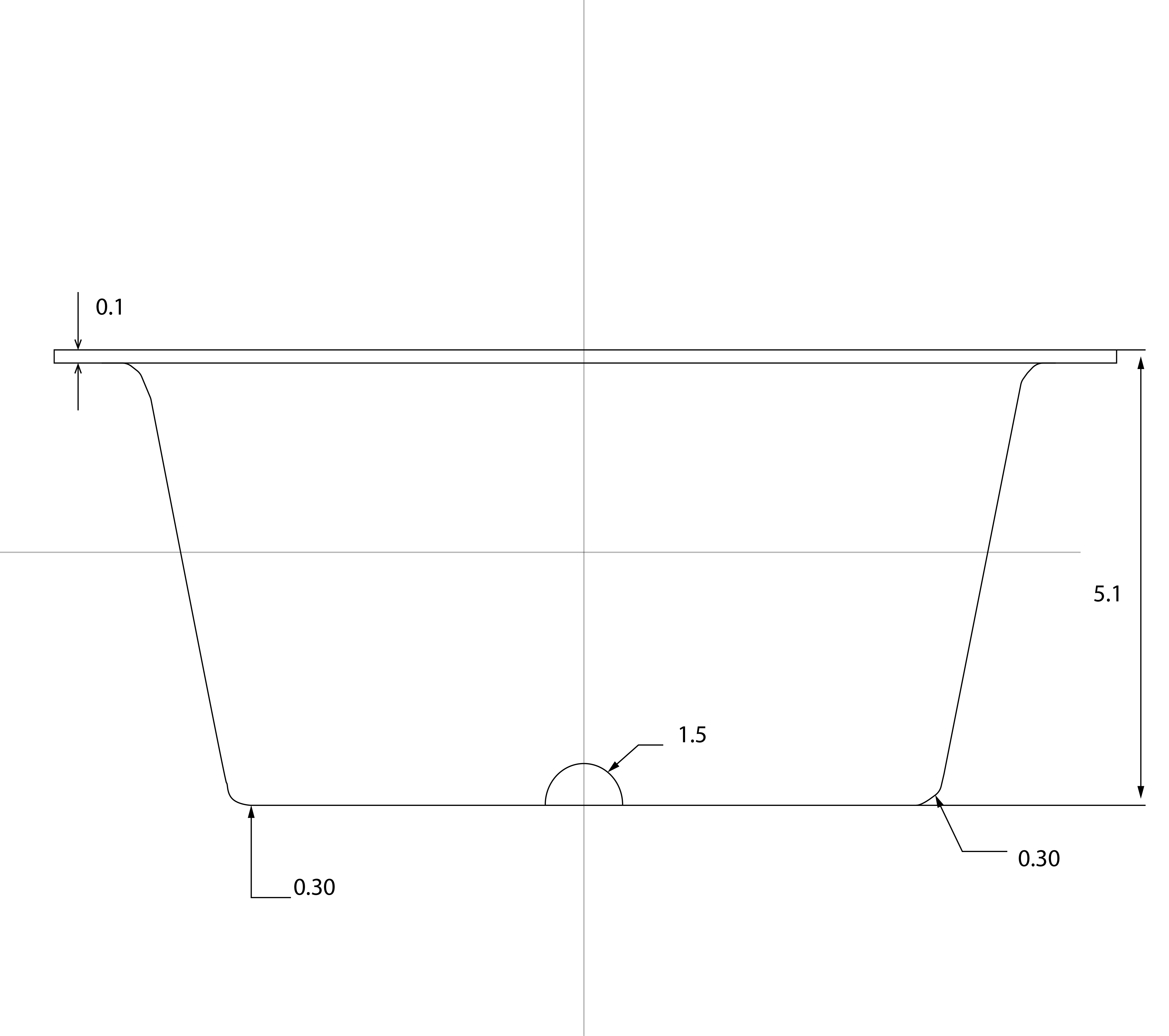

For protecting the sharp edges of the slicer at the top and slicing area, PolyPropylene(PP) plastic is used for protection.

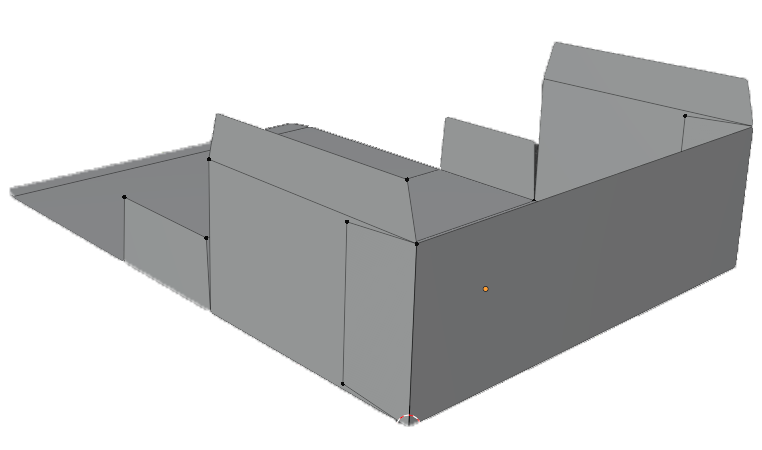

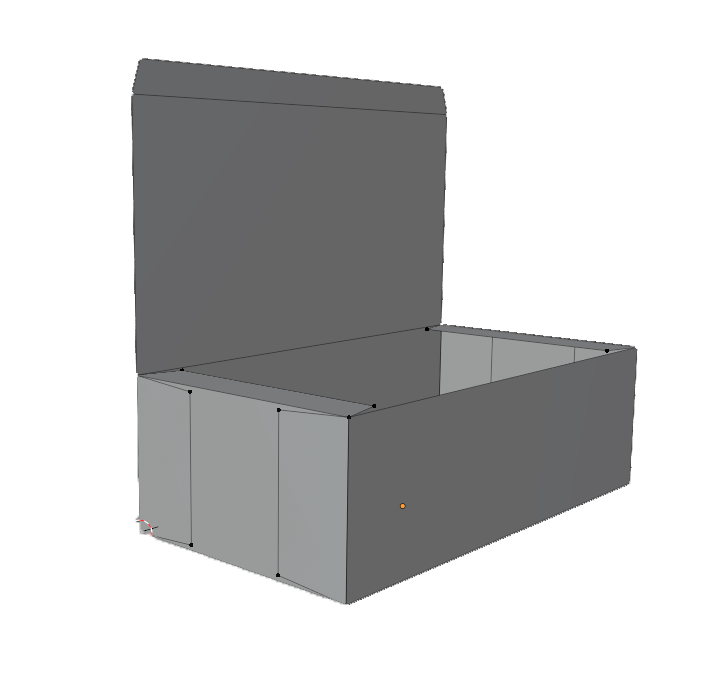

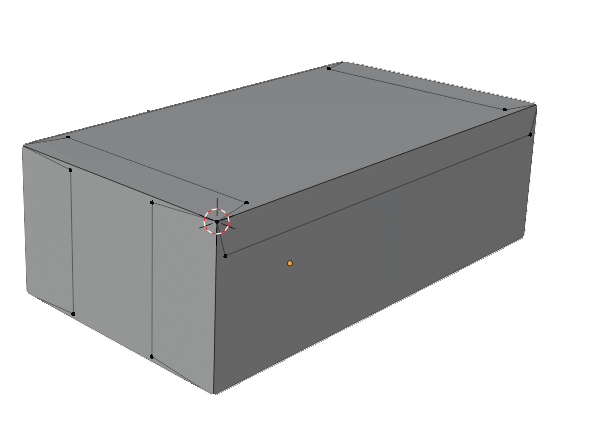

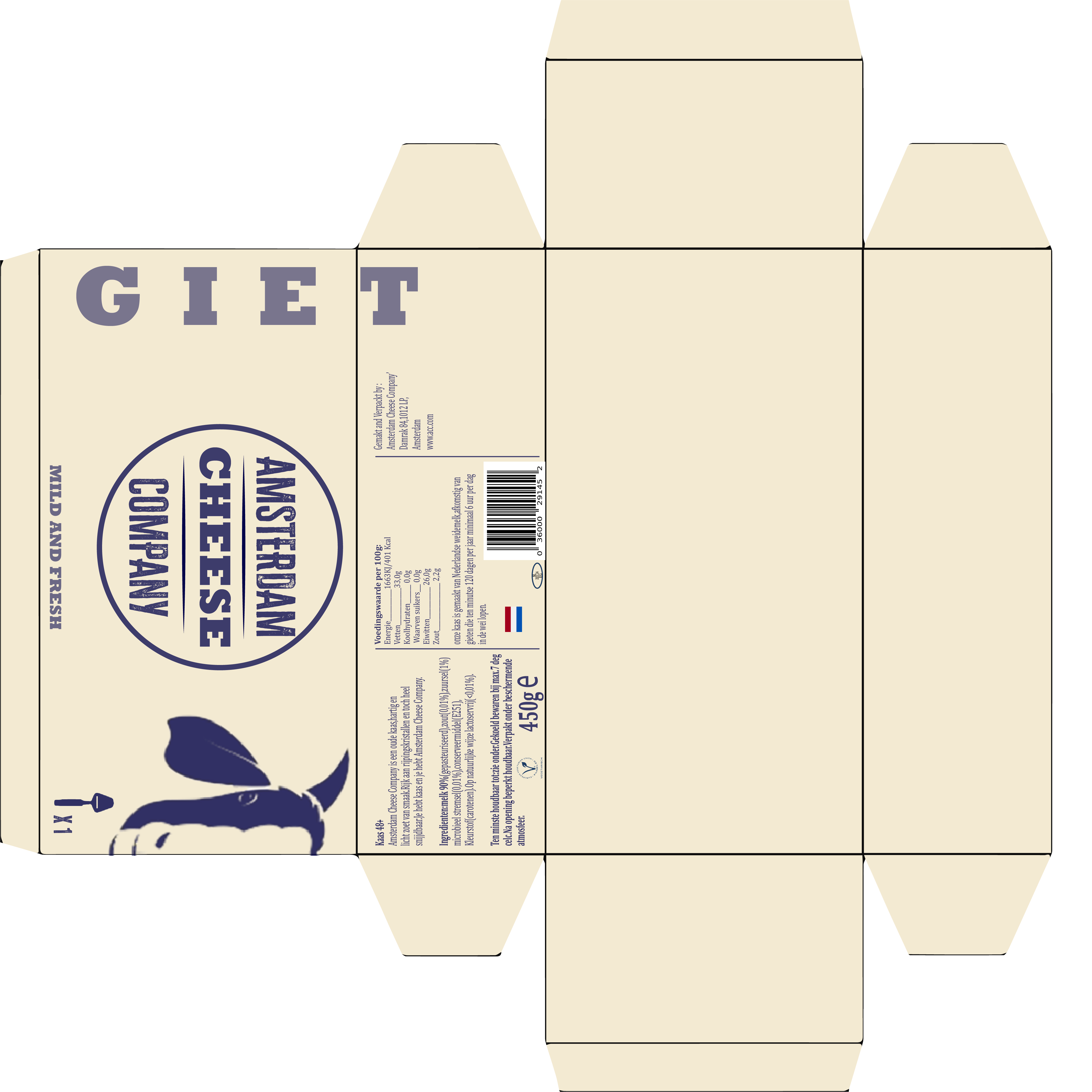

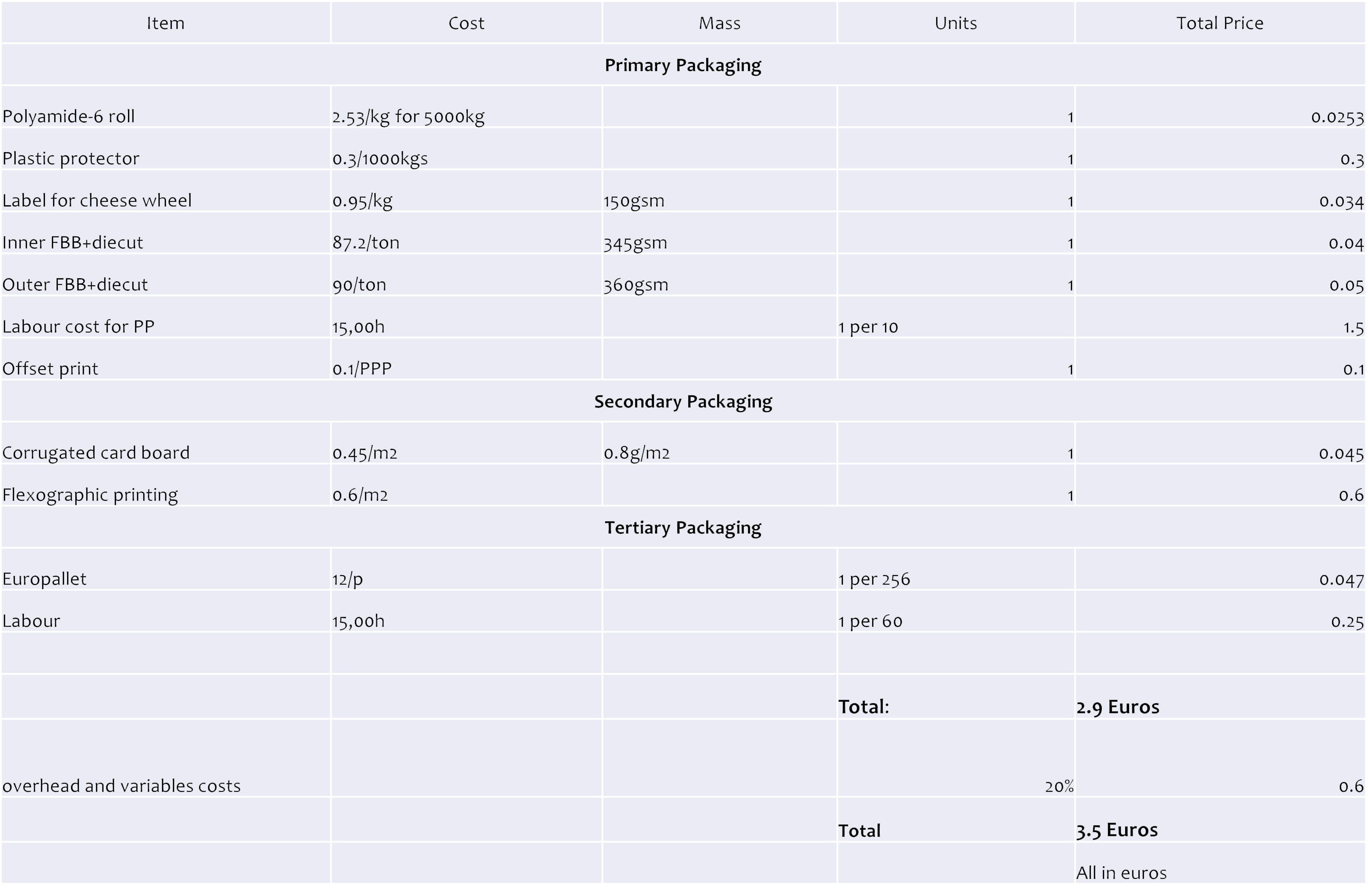

Secondary Packaging

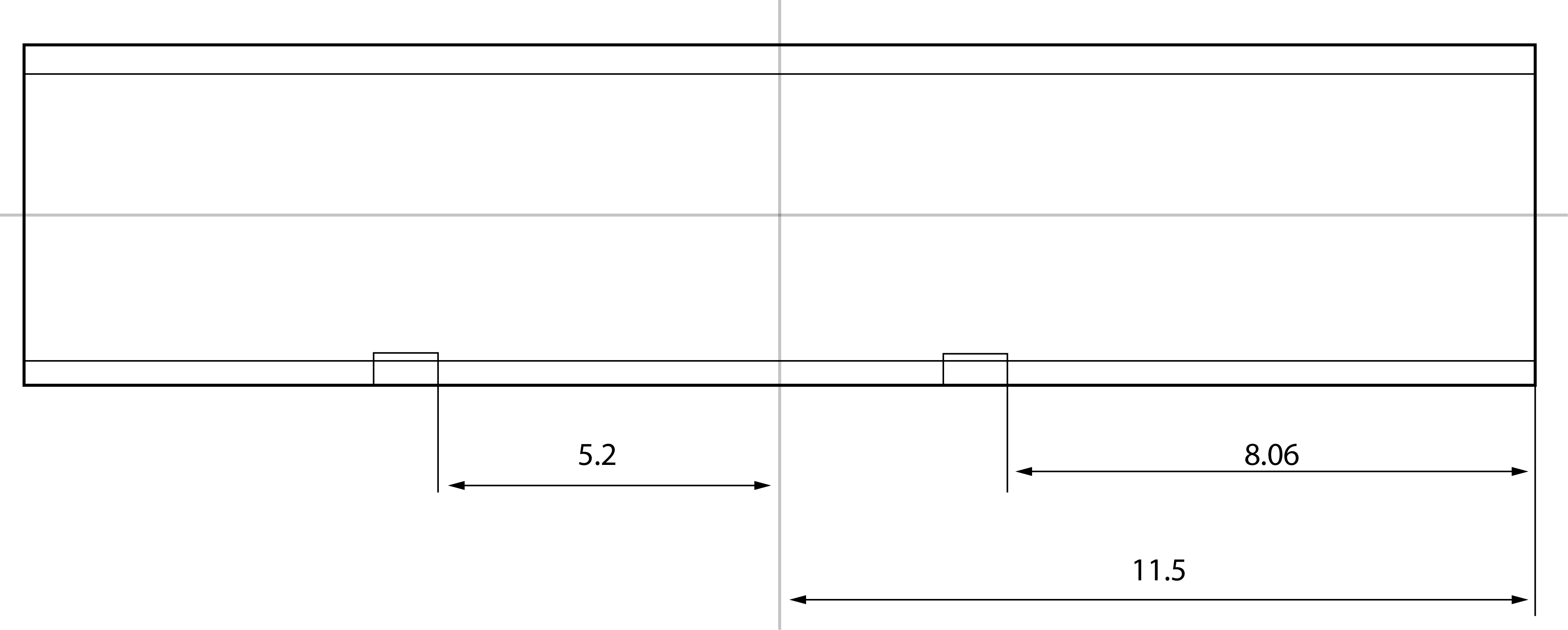

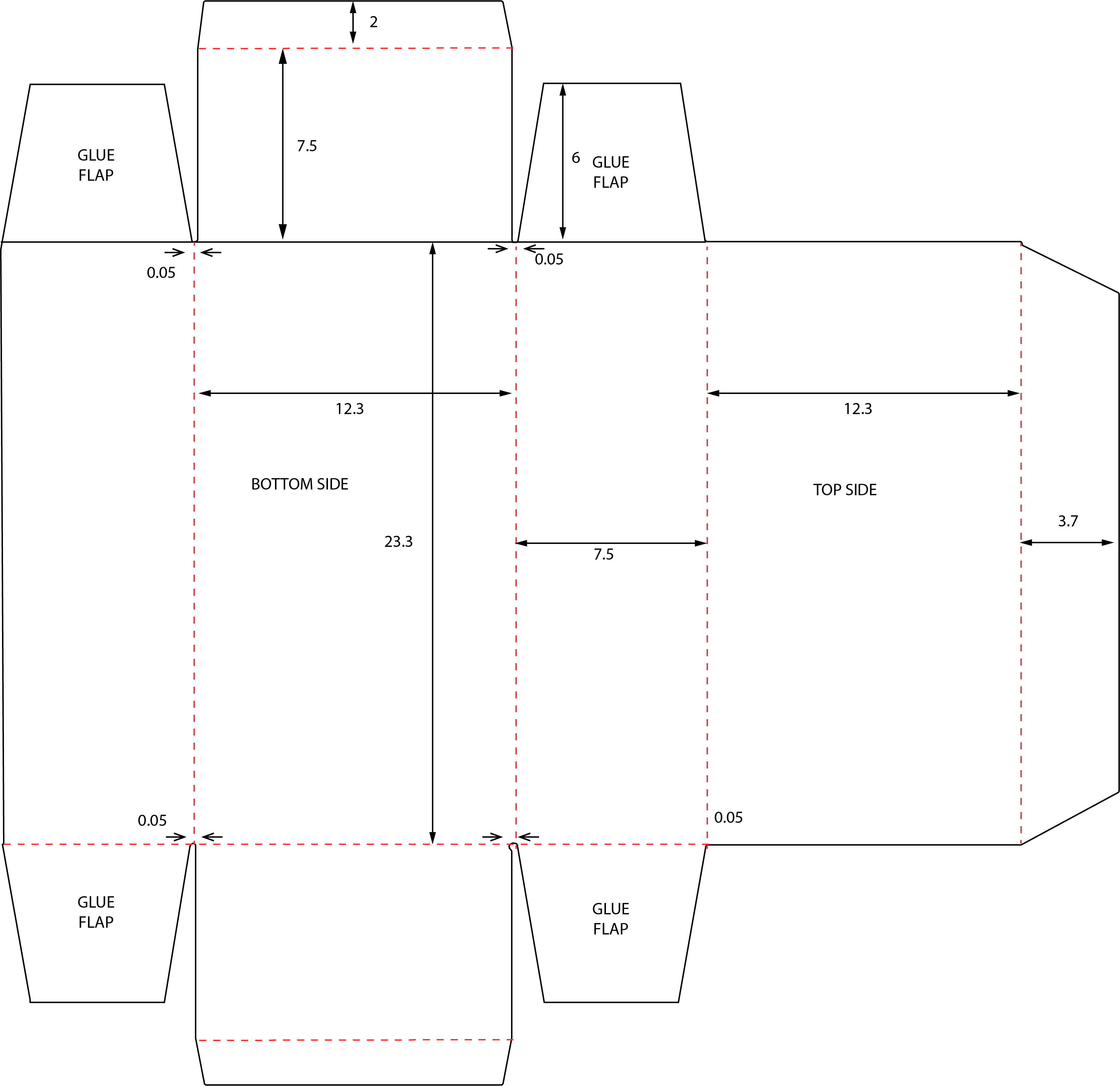

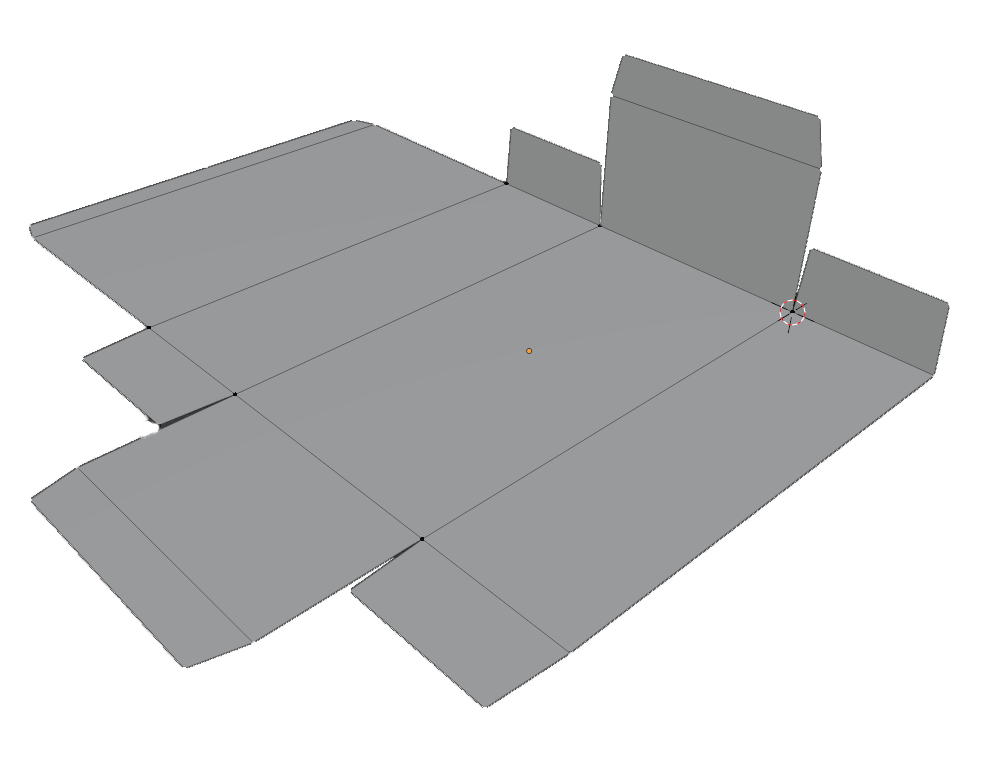

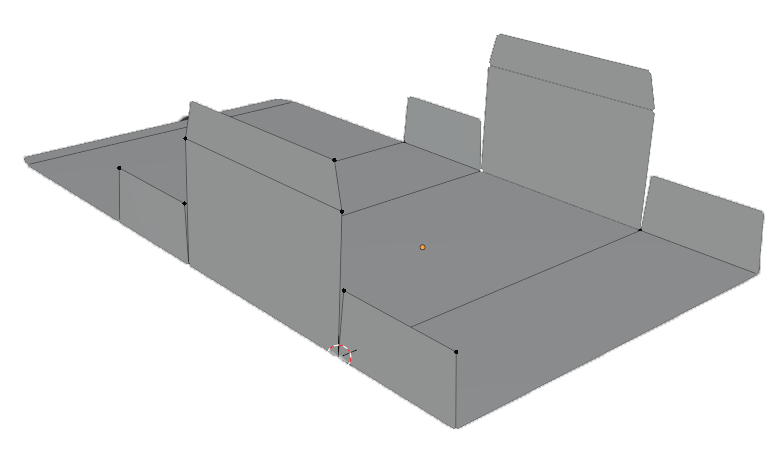

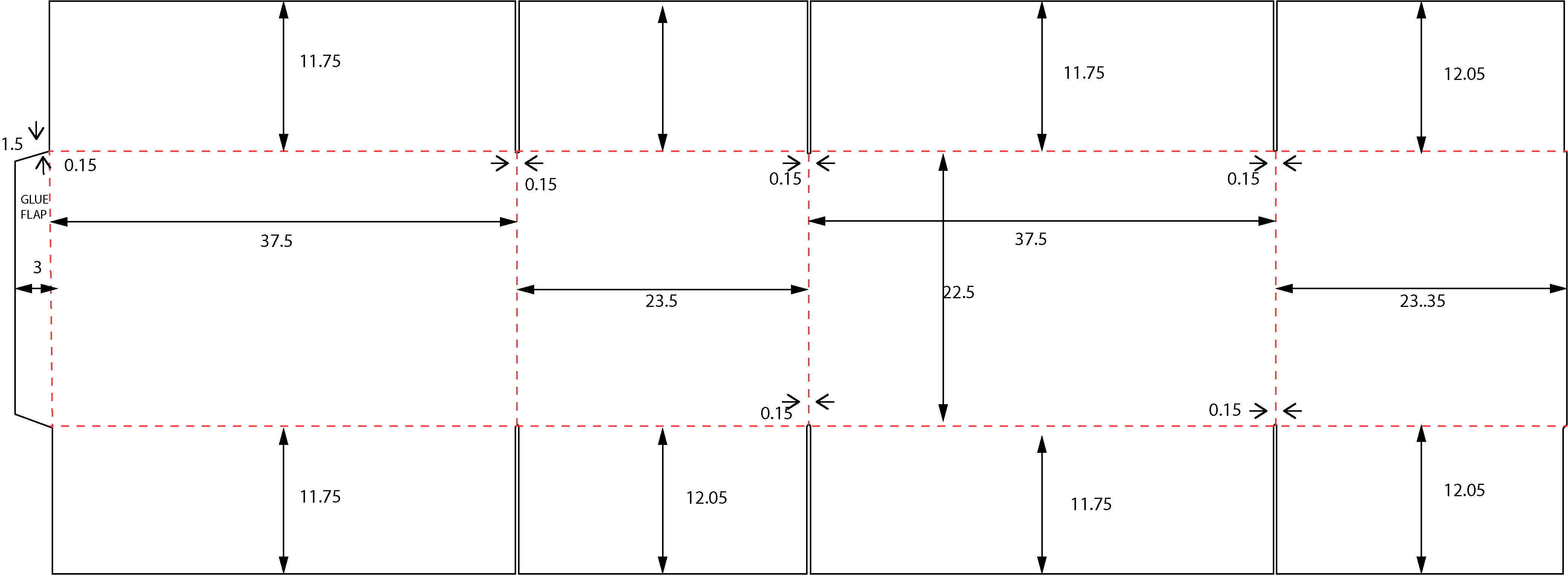

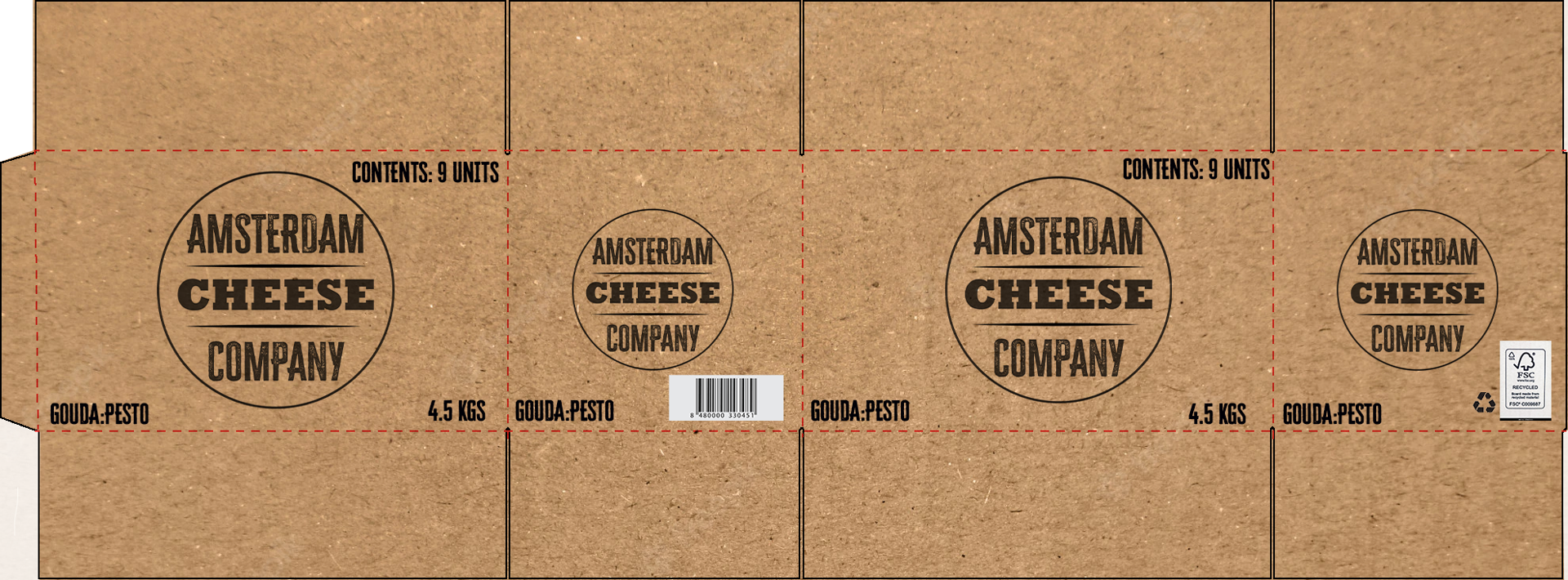

The Secondary packaging box is used for holding 9 primary packages in a 3 x 3 matrix arrangement. It is made of corrugated cardboard of 3mm thickness. Diecut is done along the folding edges.

Thickness: 3mm

Type:Single wall board with B flute

Size: 37.5x23.5x22.5cms

Flexographic Printing is used for printing the secondary cardboard.