How to make boiling of vegetables more sustainable?

Individual project

Nov 22-Feb 23

Research

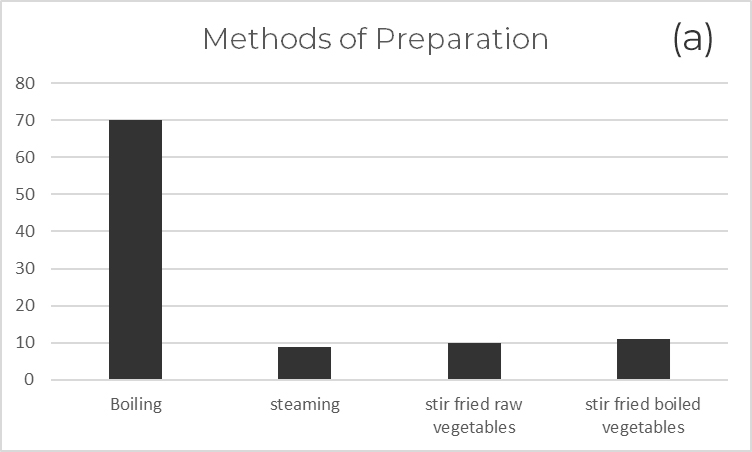

The study was conducted on different cooking methods (a)[1] and behaviours of people(n=915) who consume vegetables such as broccoli(n=567) and carrots(n=348) especially in Netherlands [1].

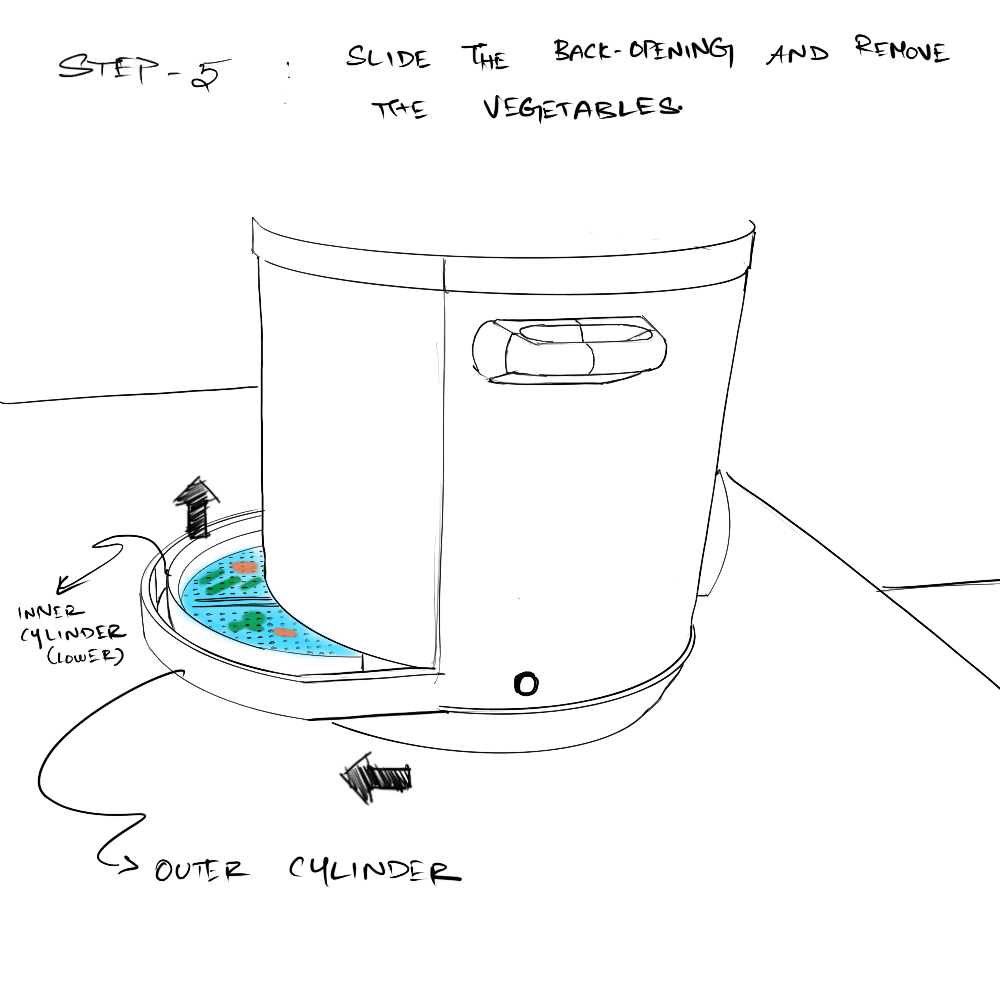

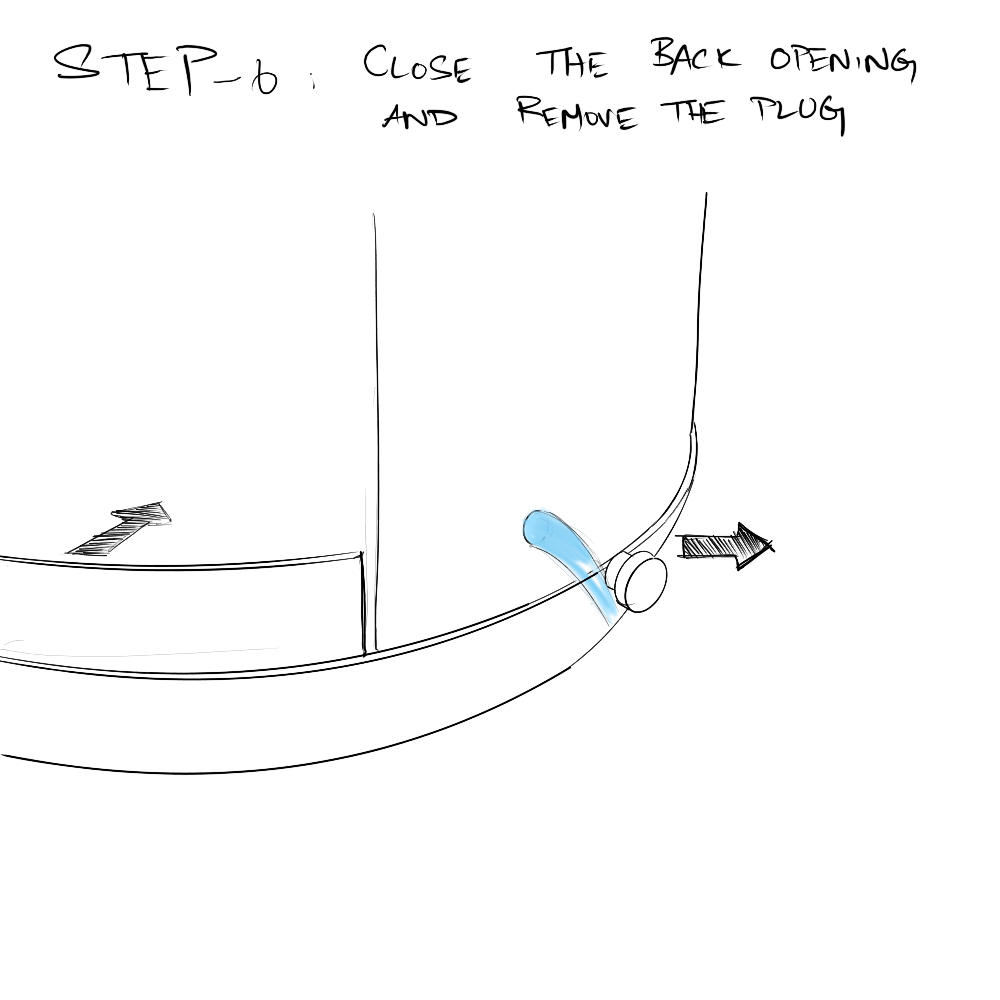

The research method used was online self reporting after cooking.The broccoli and carrots consumers are then clustered based upon texture,health,taste and water level used (b)[1].The type of start,water level, and size of vegetables are based on their habitual practice (c) [1].The results are as shown:

Another research shows that around 16% of the consumer boils (Brassicaceae vegetables) for 20mins (d)[2] and its corresponding nutrient retention (f)[2] .W-V ratio indicates the ratio of water to corresponding vegetable (e)[2] . Around 40% of the consumers use W-V ratio as 1 [2].

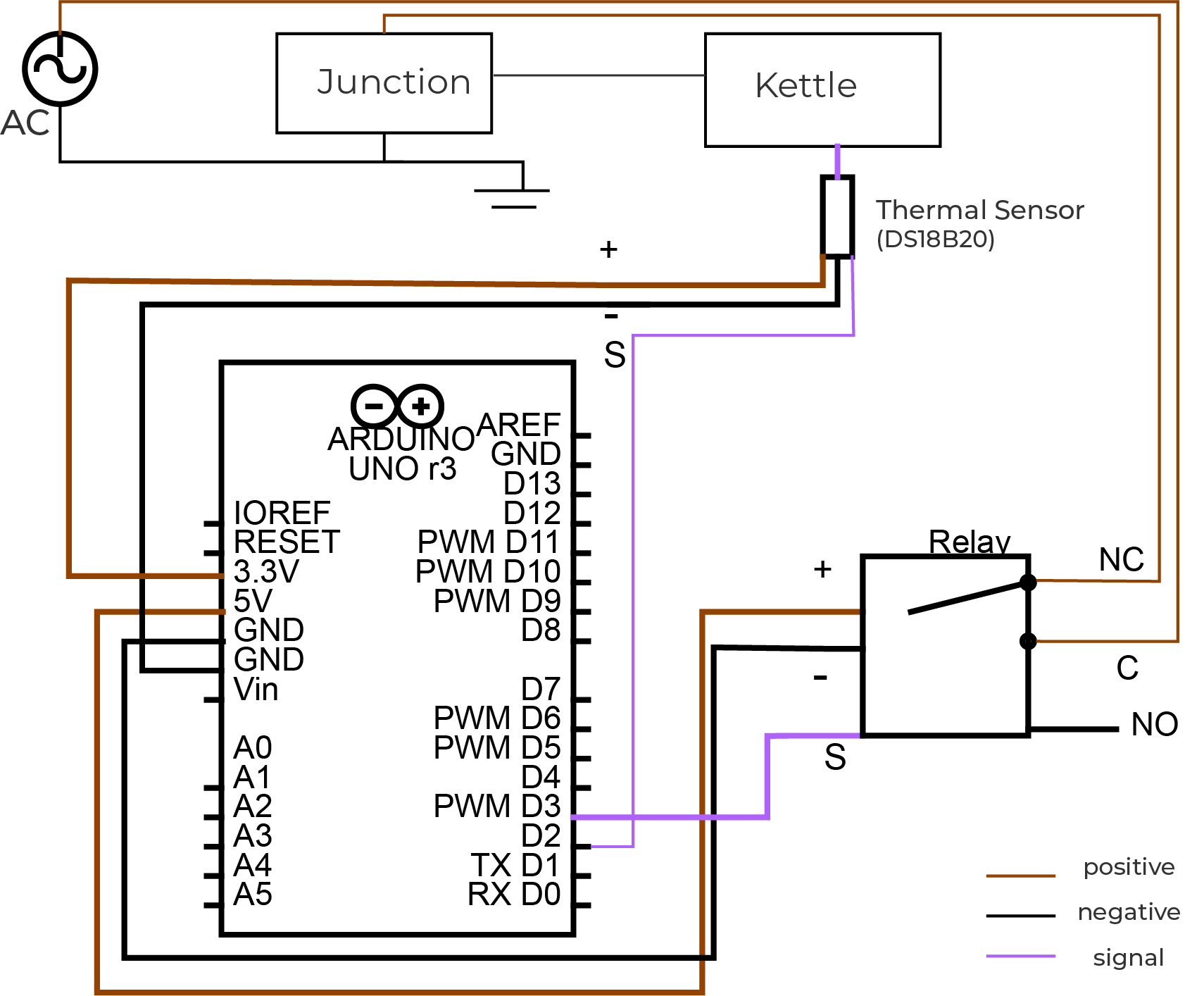

According to [3],the overall system efficiency is the product of efficiencies of production , transmission and appliance which is denoted as [3] :

Overall System Efficiency(ηS)= ηP*ηT*ηA

The focus of this project is to improve the efficiency in boiling, since it is carried out by a higher percentage of consumers.According to [4], the energy consumption of kettle compared to other appliances are shown as below in (g)[4] and (h)[4]:

Some other researches [3] indicate that consumers does not use the residual or passive heat which is available,consumers use twice the amount when doing a hurried boiling etc.

Key Conclusions

-

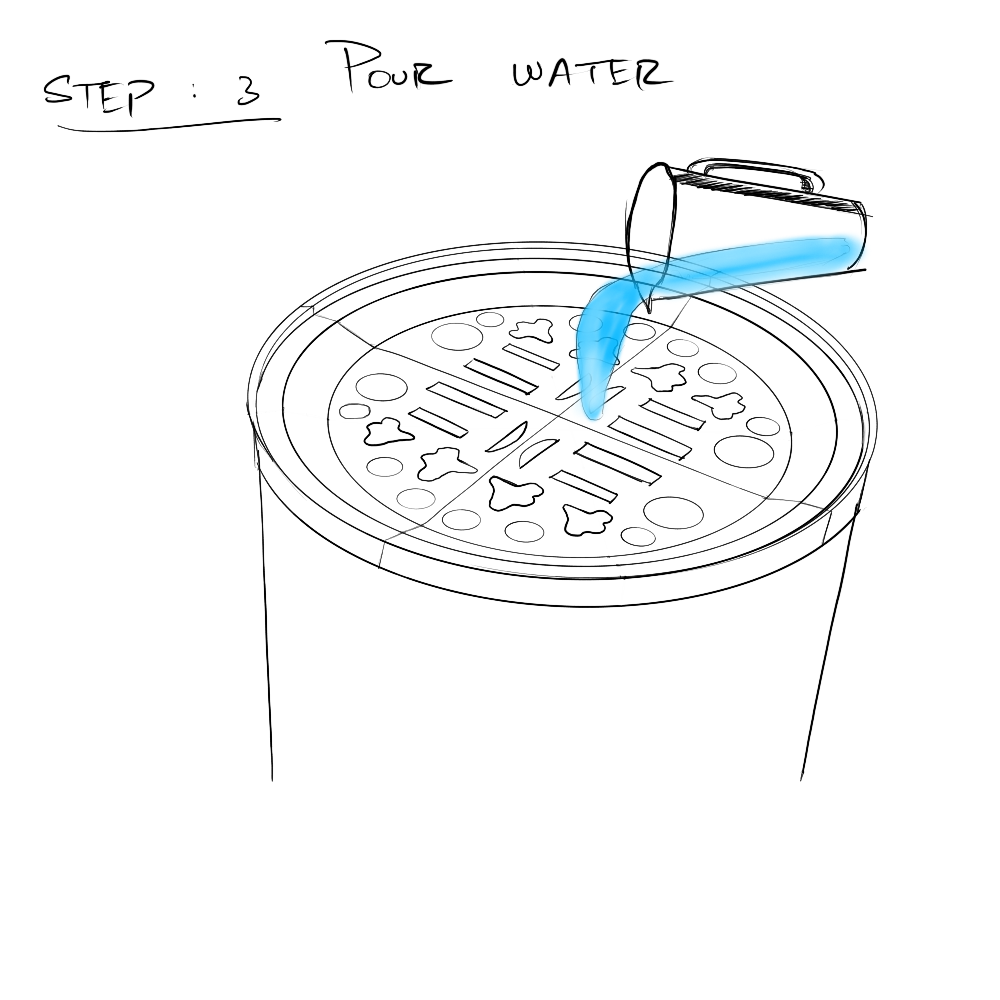

Water level used is directly proportional to time required for

boiling, energy spent for boiling

and loss of nutrients. - Low level of health consciousness among people.

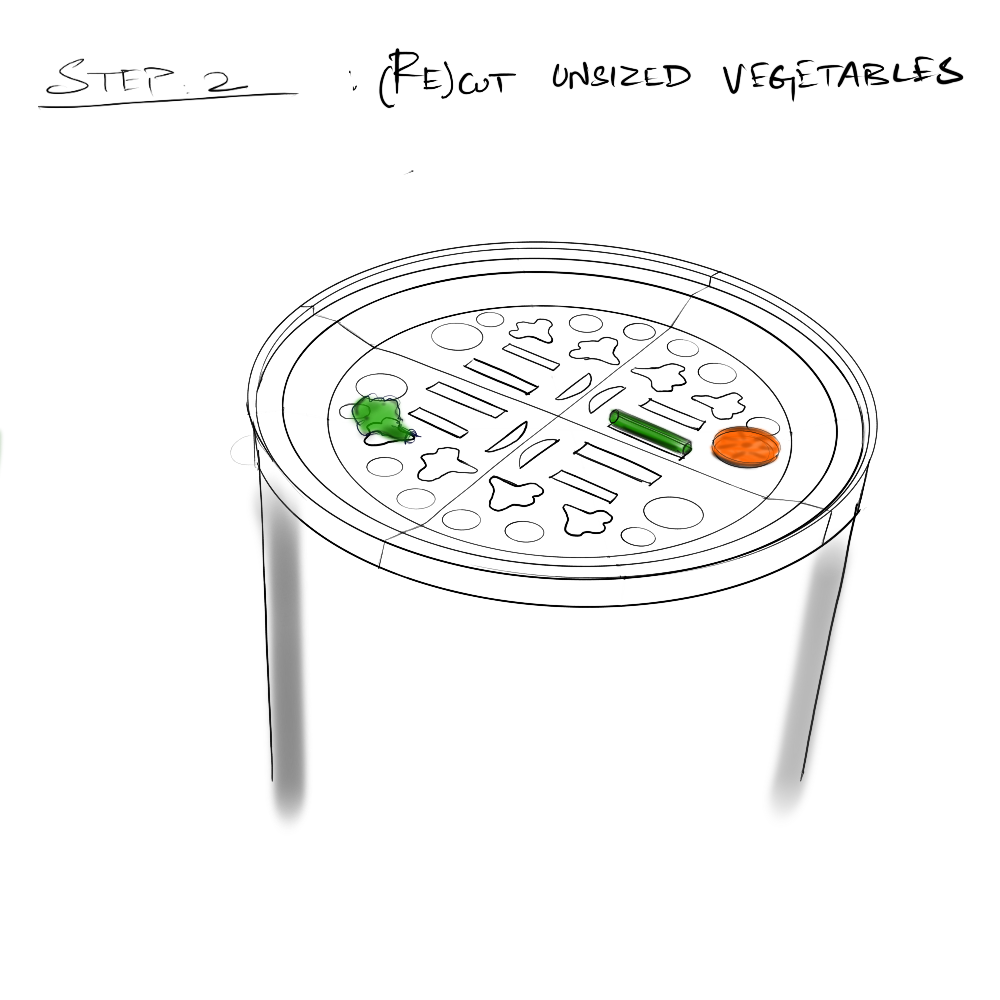

- Higher percentage of people who do not cut or slice the vegetables into proper pieces.

- Water level and type of start is based upon their habitual practice.

- Texture is important to predict the doneness of vegetables.

- Kettle is the least energy consuming applicance compared to other day-to-day appliances.

Requirements

-

The final appliance should use the principle of electric water

kettle as it has very low amount of

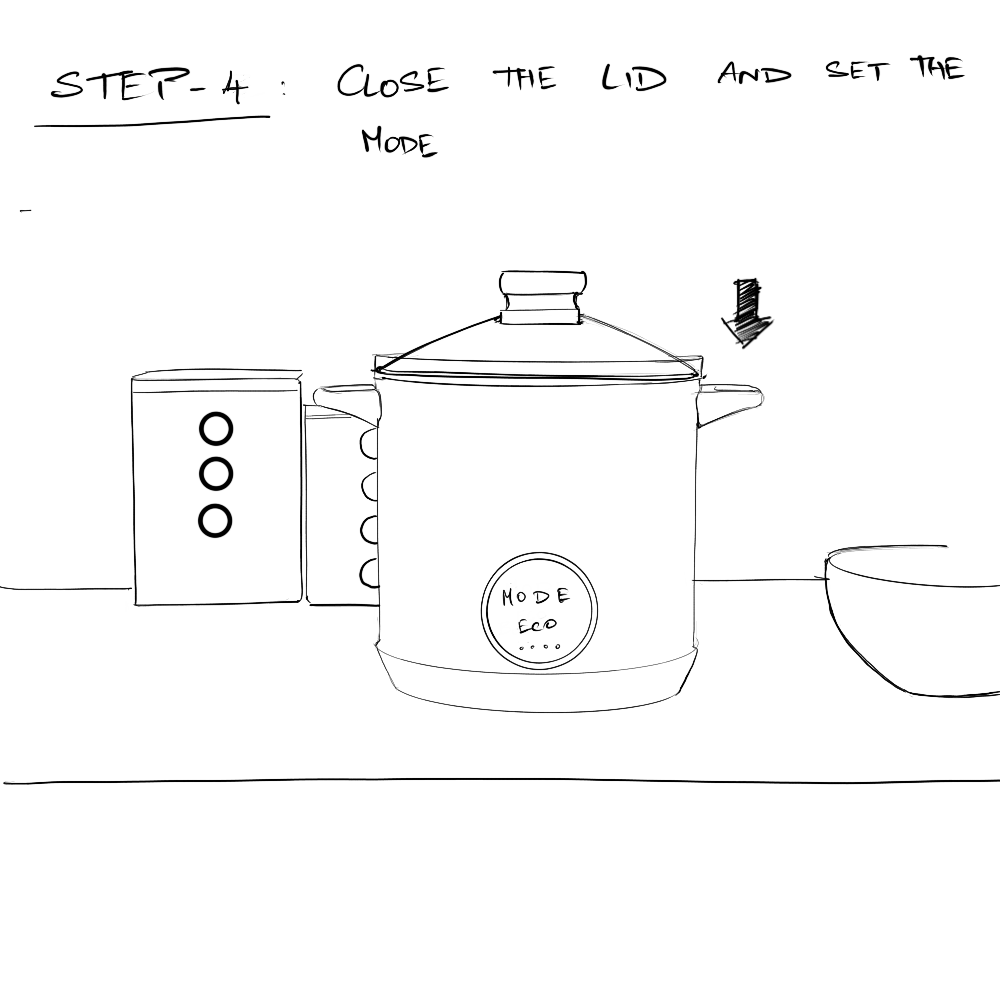

specific energy consumption. - The appliance should boil(100°C) and steam(95°C)the vegetables.

- The boiling of vegetables should be visible.

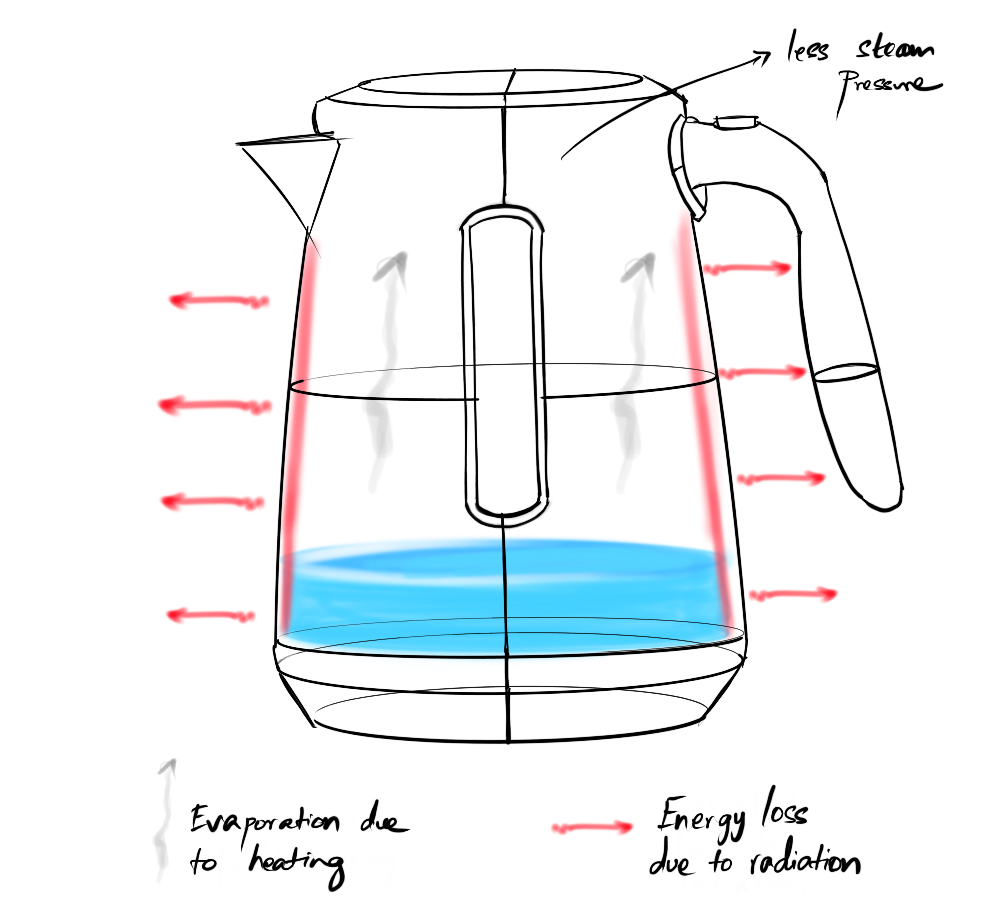

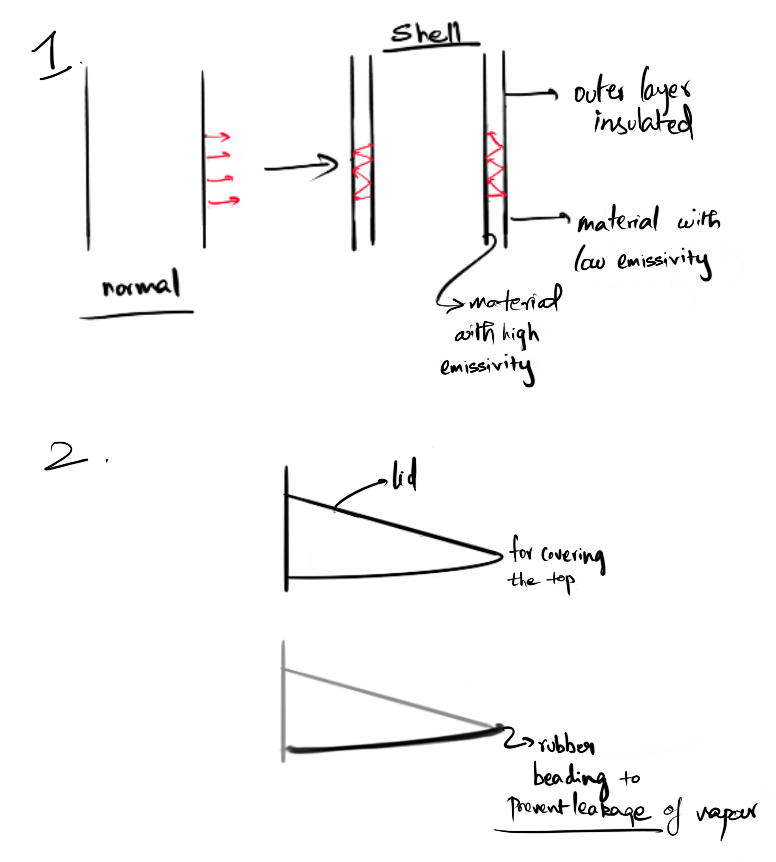

- The appliance should preserve the radiated heat during boiling or steaming the water.

Calculation

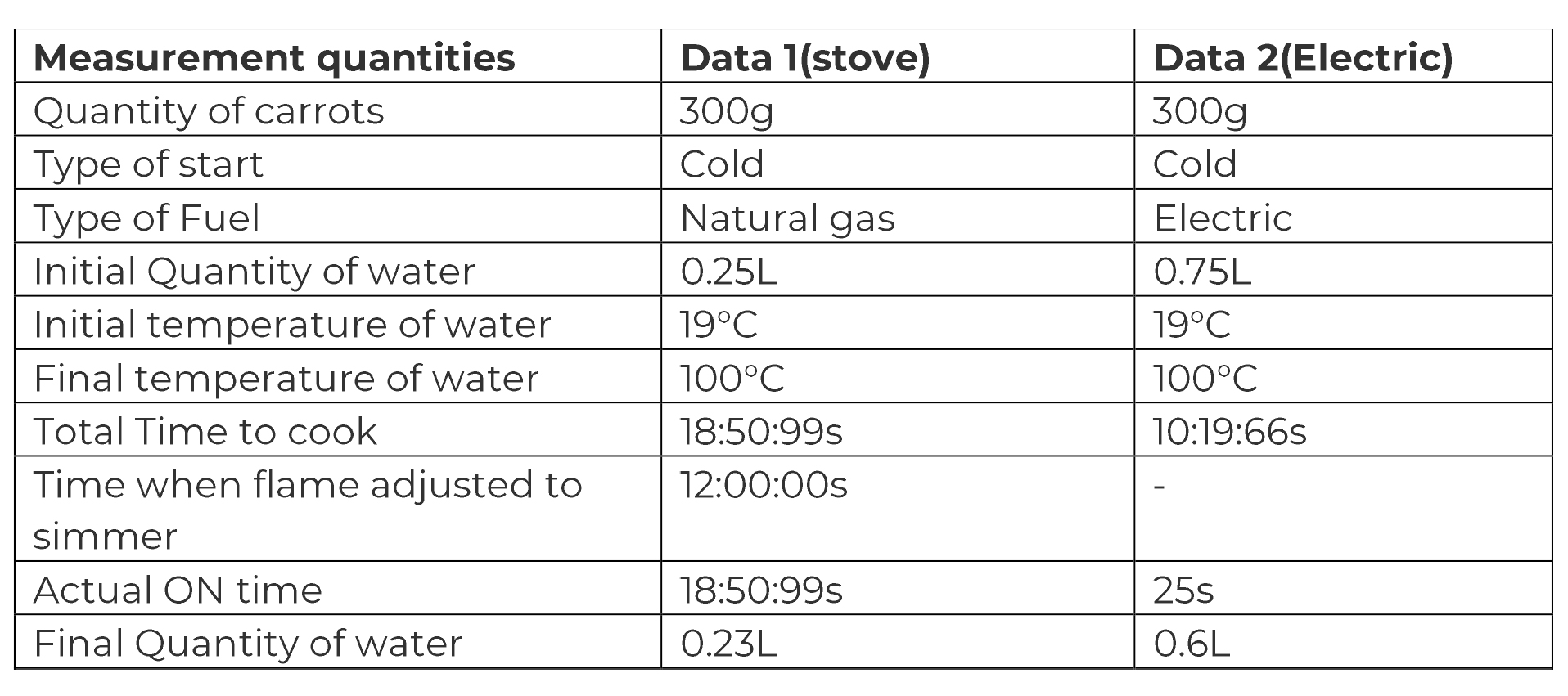

The cooking of the carrots in the stove undergoes second law of thermodynamics. The heat is transferred by conduction from bottom (outside to inside) . The heat is further transferred to water and carrot with convection. Finally a proportion of heat is lost by radiation into the air.

Applying second law of thermodynamics,

Q=m.C.ΔT

Where

m is the mass of the container

C is the specific heat capacity of medium (Cw=4.186 KJ/kg

°C,Css=468 KJ/kg°C)

ΔT is the difference of final and initial

temperatures(ΔT=100°C -19°C =81°C or 354K)

mw=Density of water(ρw).Volume of

water(Vw) =1000 kg/m3x 0.25L x 0.001m3

=0.25Kg

mss=1.7kg

Heat transfer coefficient of carrots(hcarrots)=12 W/m2K

Area contact with stove=0.5m2

Heat transferred to water(Qw)

Q w=m.wCw.ΔT

=0.25kgx4.186 KJ/kg °Cx81°C

=84.7KJ

Heat transferred to container(SS316)(Qss)

Q ss=m.ssCss.ΔT

=1.7kgx468 KJ/kg °Cx81°C

=64.4KJ

Total Heat transferred(Qtotal)=84.7+64.4KJ=149.1KJ

% of heat transferred to water=(84.7/149.1) X 100 = 56.8%

% of

heat transferred to container = (64.4/149.1) X 100 = 43.1%

Quantity of heat transferred to carrots(Qcarrots)

Qcarrots=hcarrots.A.ΔT

=12W/m2Kx0.5m2x354K

=2124W = 2.124 KW or KJ/s

Hence the carrot receives 2.124 KJ per second from water .

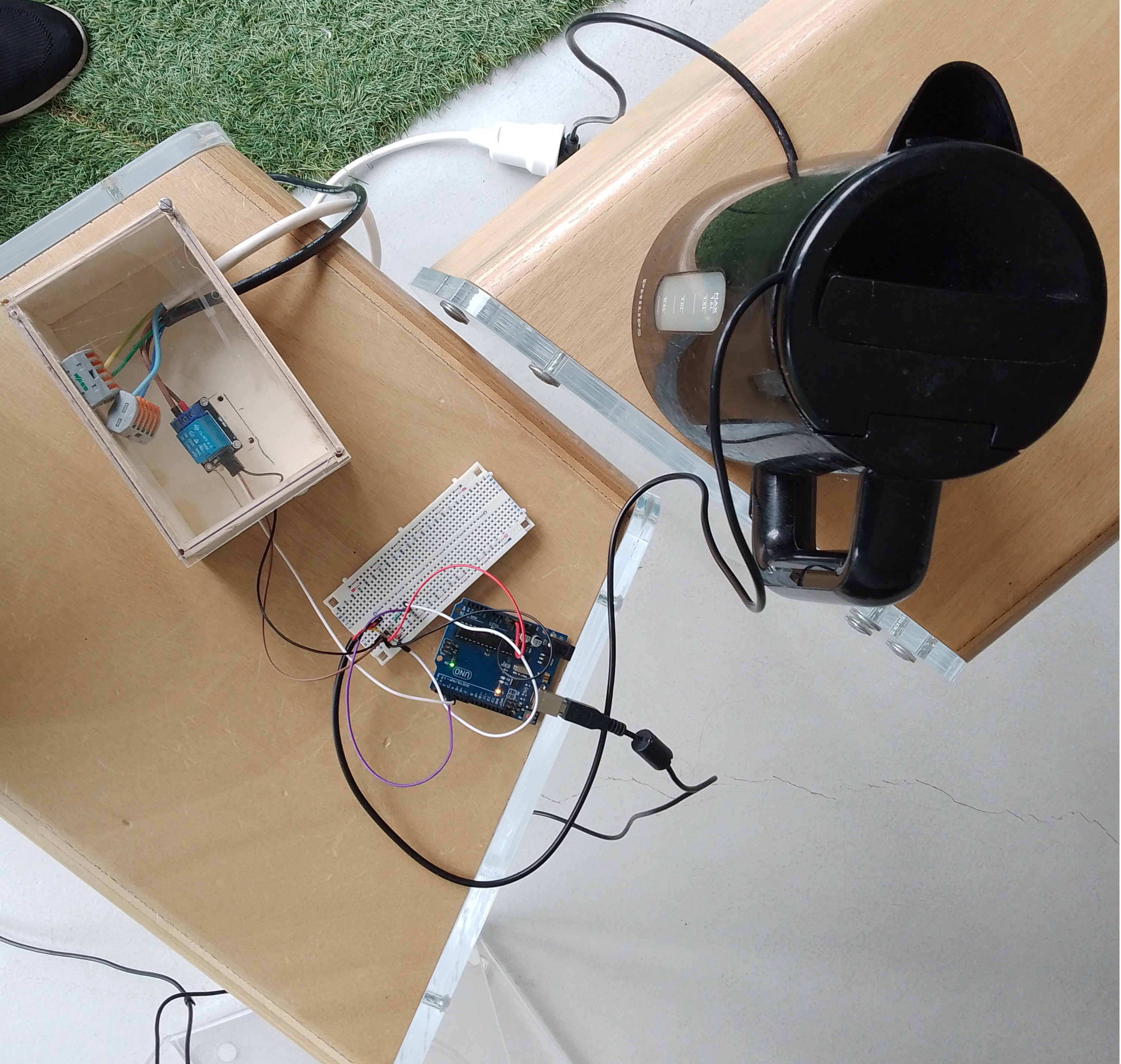

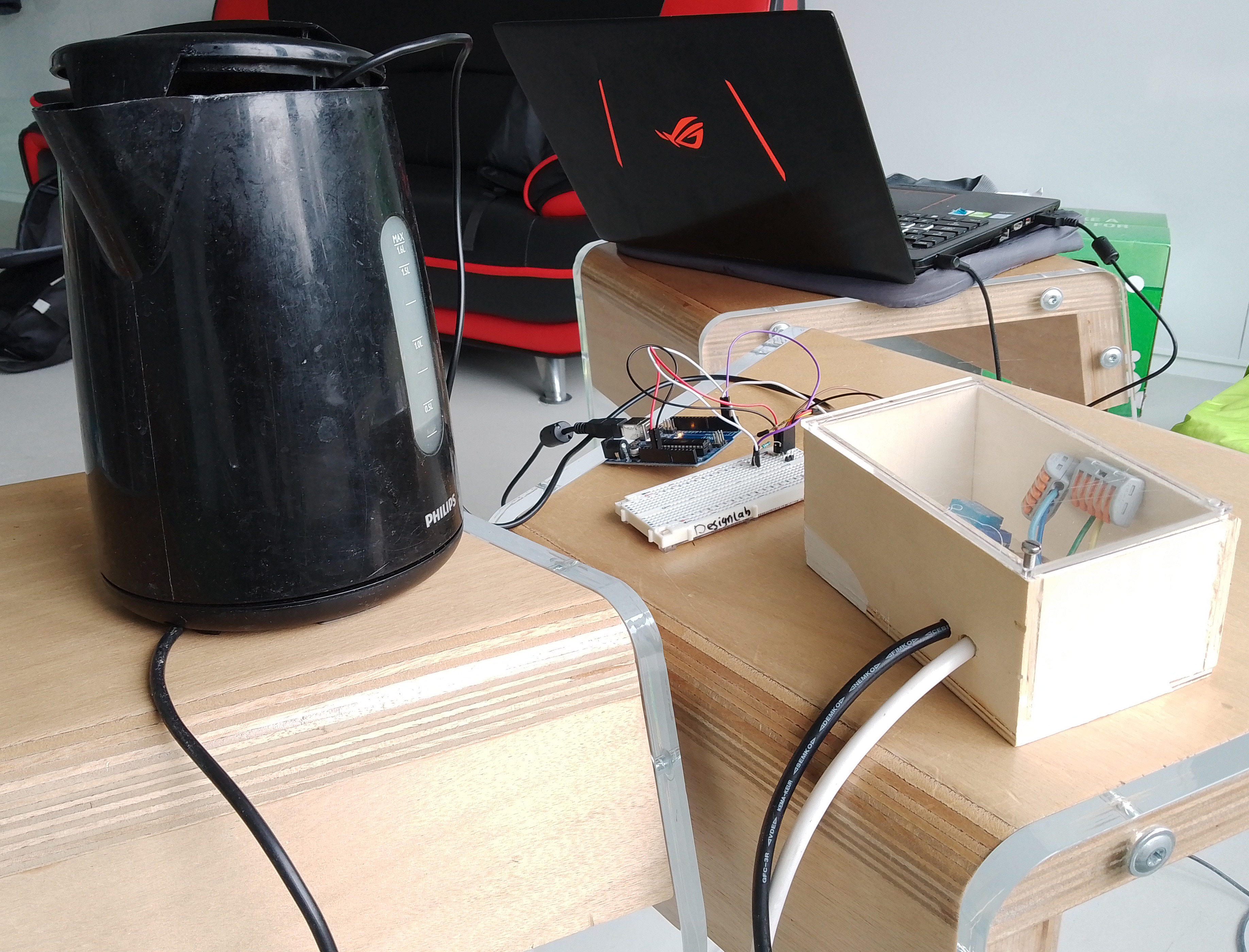

The heat transferred by resistive element to water undergoes Joule’s law of heating,

Joule’s law of heating(H)= I2.R.t

Where

I is current in Amps(9.1A (P=V.I))

R is the resistance of coil in ohms(24Ω)

t is the time period (s) through which the kettle is ON = 25s(from

testing)

H= 9.1x9.1x24x25

=49686 J = 49.686 KJ

Energy transferred by kettle / Energy transferred by stove = 49.6 / 149.1 = 1/3 (approx.)

It is seen that the kettle requires only 1/3 of energy to do the same application.

Design

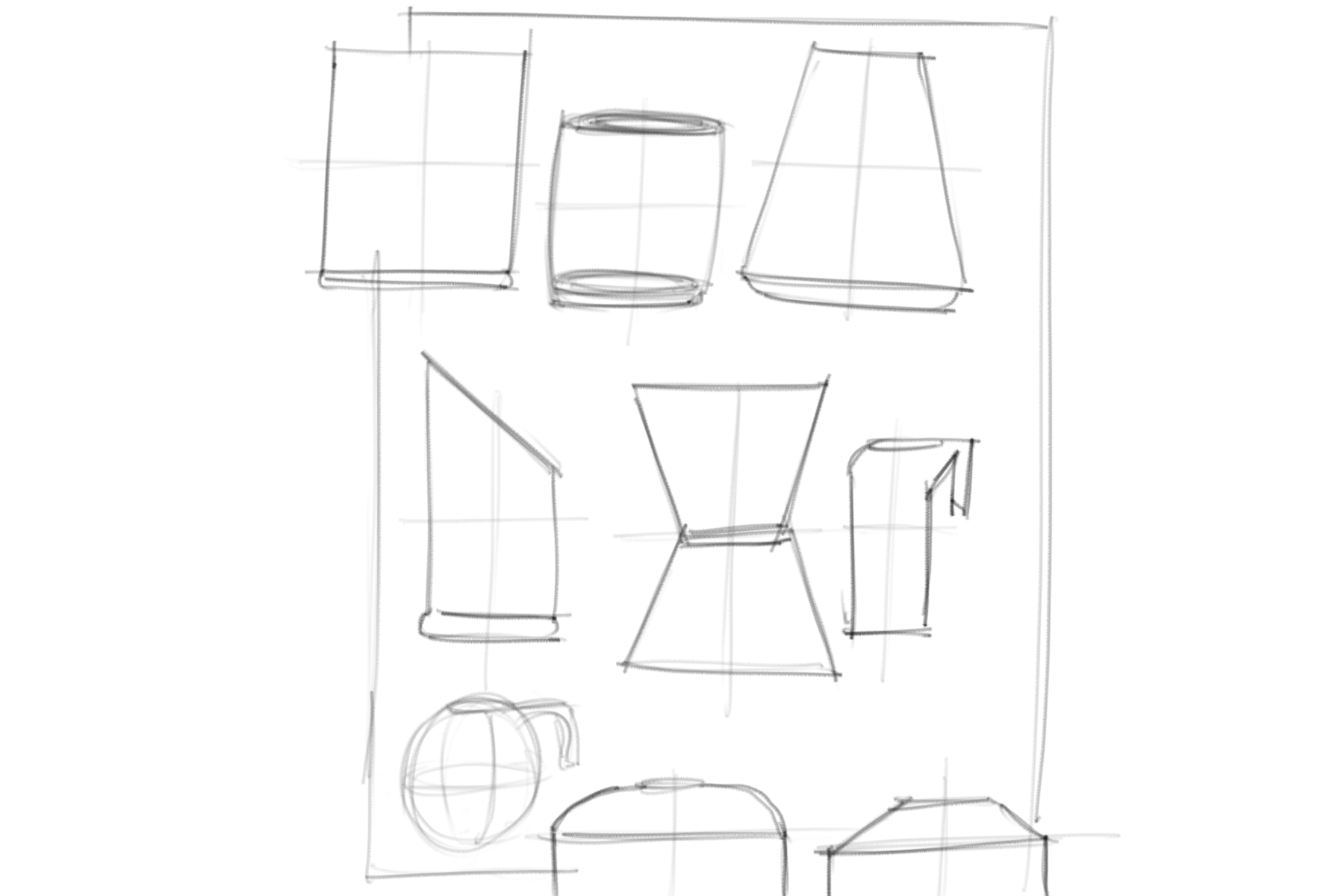

Some ideation is done with profiles to determine the final profile.

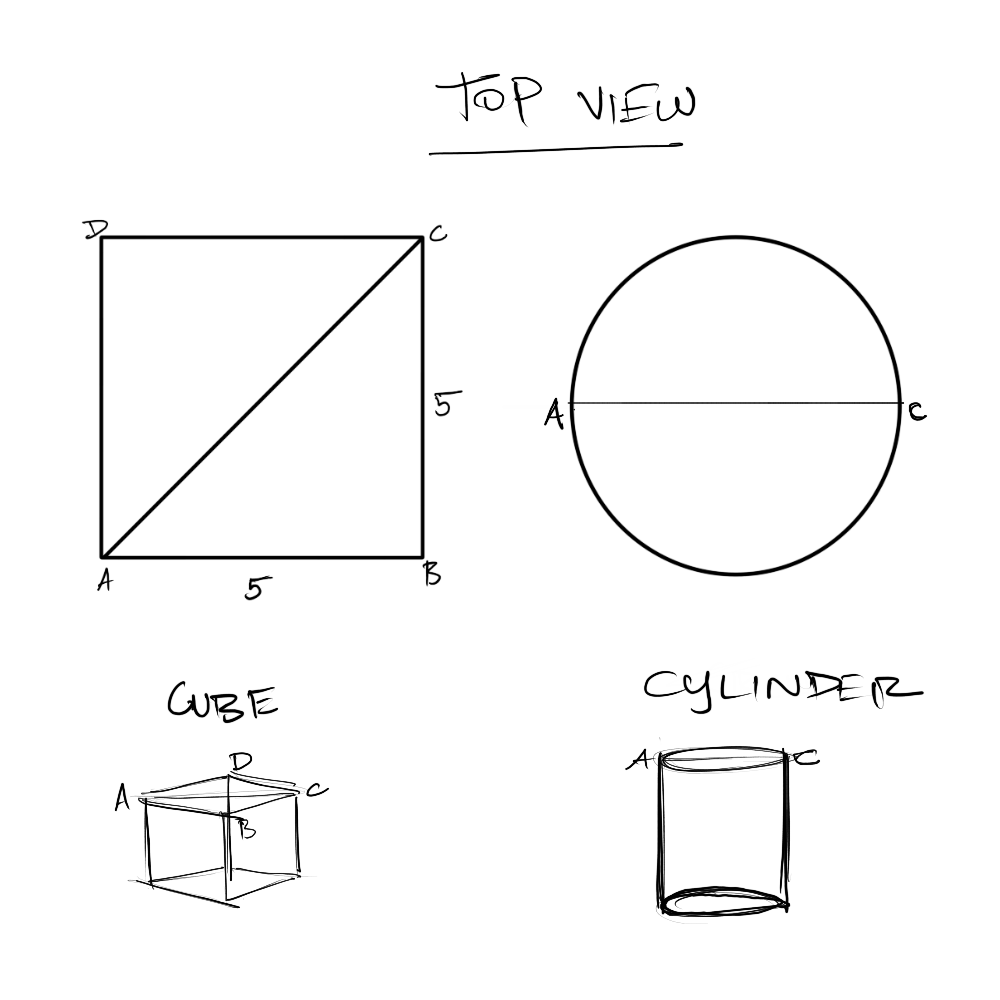

Consider a cube with a side of 5m3.

Volume of the cube(a3)=125m3.

From cube’s top view:AC2 = AB2+BC2

=52+52

=5√2

=7.1m

This will be the diameter of cylinder

keeping height 5m as constant.

Volume of cylinder(Vcylinder)=πx r2xh

=3.14x3.5x3.5x5

=192.32m3.

For the same height (5m) , the cylinder has higher

volume than cube.

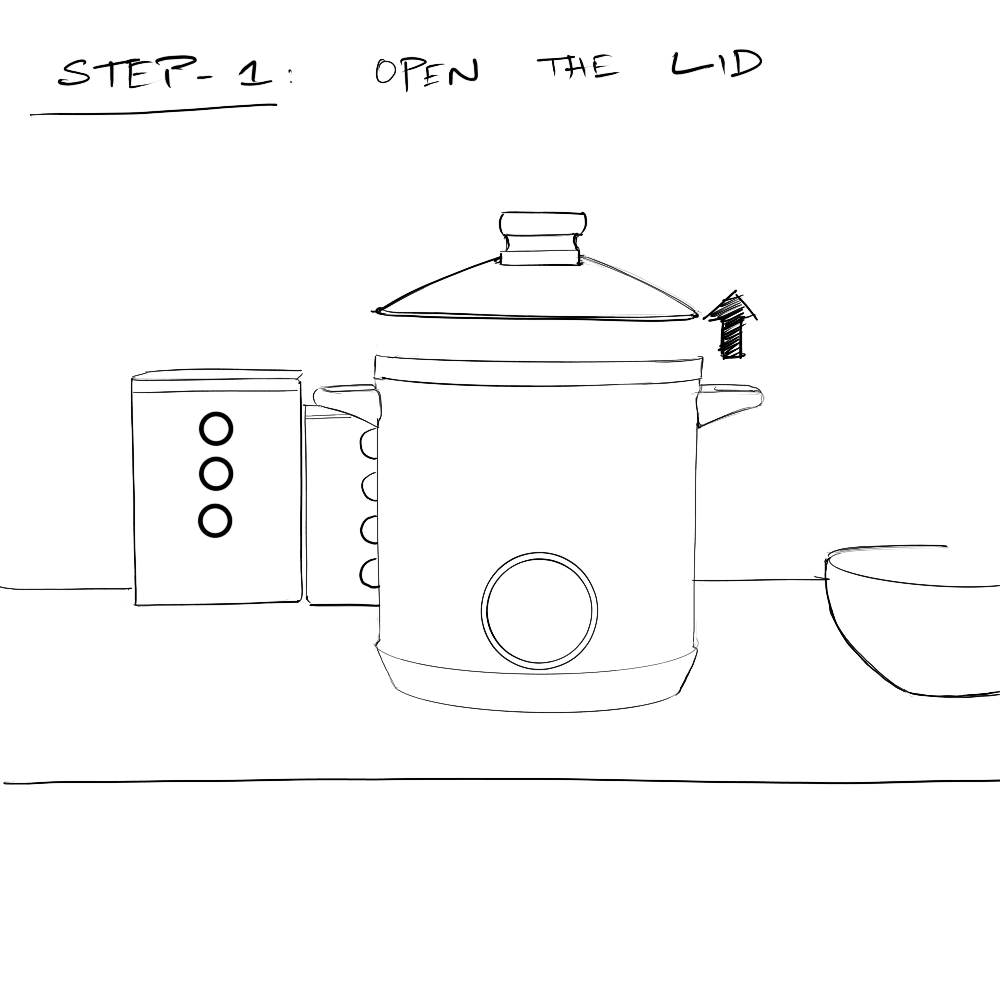

The working of existing kettle are analysed and noted.

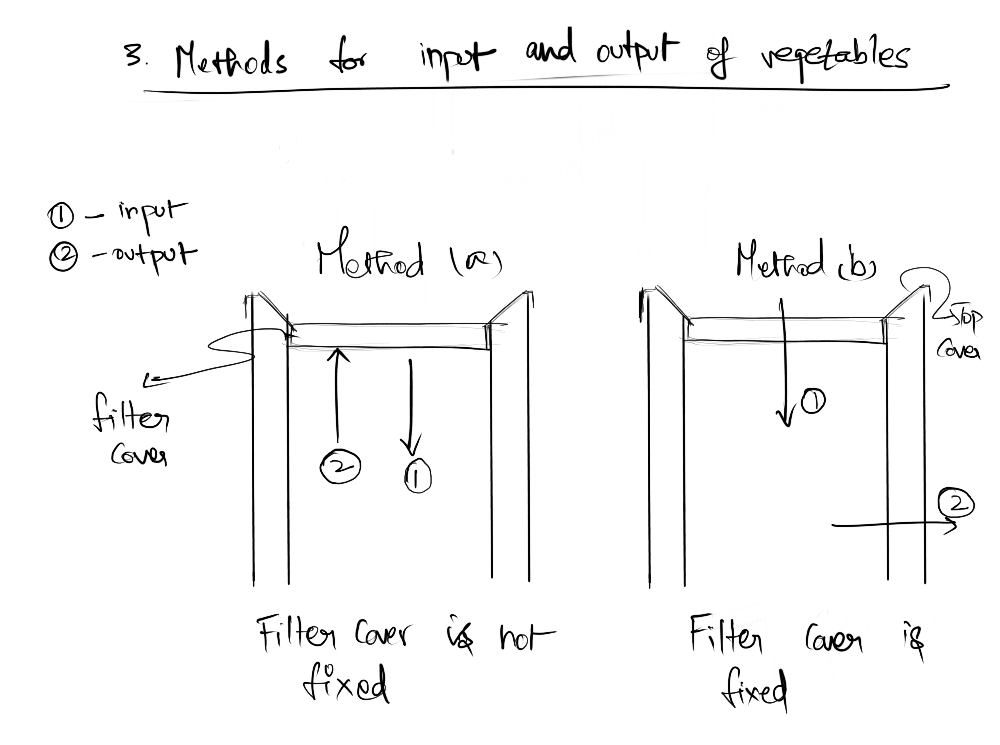

Some solution and design decisions(based on research) are made.

Usability

References

[1]Bongoni, R., Verkerk, R., Dekker, M., & Steenbekkers, L. (2015). Consumer behaviour towards vegetables: a study on domestic processing of broccoli and carrots by Dutch households. Journal of Human Nutrition and Dietetics , 28(3), 219–225. https://doi.org/10.1111/jhn.12245

[2] Bongoni, R., Steenbekkers, L., Verkerk, R., Van Boekel, M., & Dekker, M. (2013). Studying consumer behaviour related to the quality of food: A case on vegetable preparation affecting sensory and health attributes.Trends in Food Science and Technology, 33(2), 139–145. https://doi.org/10.1016/j.tifs.2013.08.004

[3]Hager, T. J., & Morawicki, R. O. (2013). Energy consumption during cooking in the residential sector of developed nations: A review.Food Policy,40,54–63. https://doi.org/10.1016/j.foodpol.2013.02.003

[4]Oberascher, C., Stamminger, R., & Pakula, C. (2011). Energy efficiency in daily food preparation. International Journal of Consumer Studies,35(2),201–211. https://doi.org/10.1111/j.1470-6431.2010.00963.x